Roller Conveyors

Tailor-made and uniquely flexible

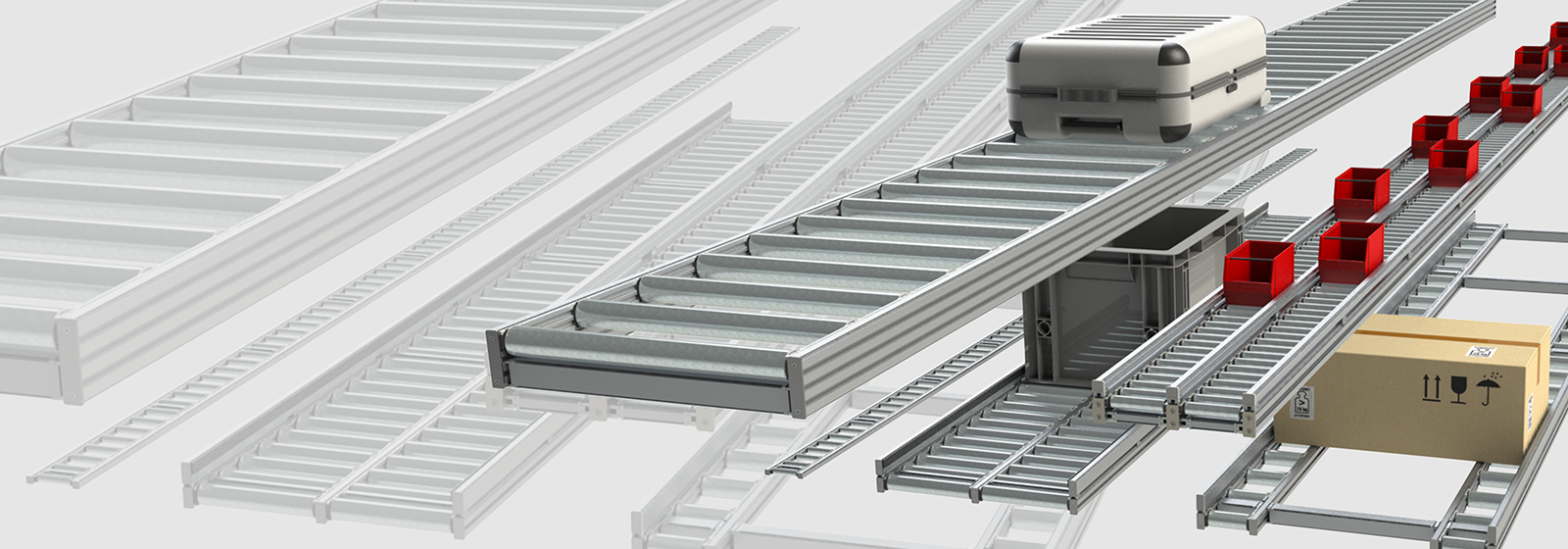

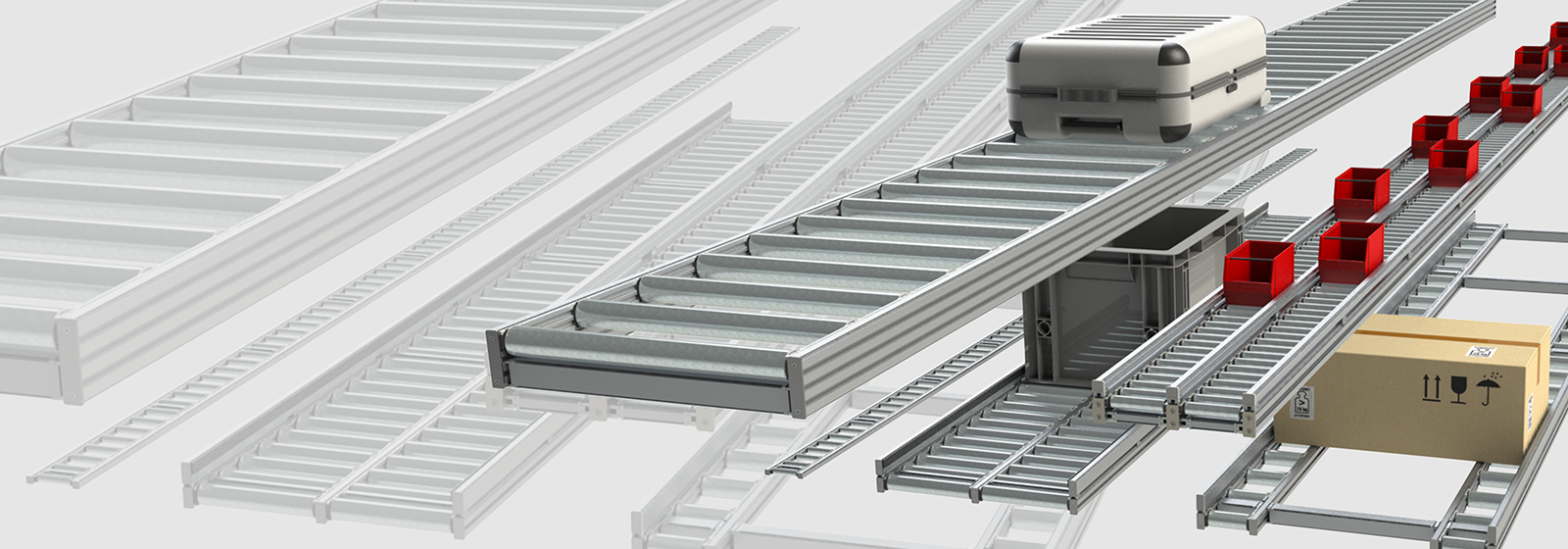

The RB4020 and RB5025 gravity roller conveyors from Montech are unique in their design and offer a new dimension of flexibility. Their structure is optimally adapted to the material being conveyed. There are no predefined track widths, center distances or track lengths for Montech roller conveyors. Instead, idler rollers in two different diameters are available, as well as a basic structure in various designs and conveyor widths, center distances and track lengths that can be selected to a fraction of an inch, with or without end stops. Accessories include, for example, a selection of side guides and a substructure made from the precise MPS aluminum profile system.

Montech roller conveyors – precision meets efficiency

Our roller conveyors are the ideal solution for the in-house transportation of workpieces and goods. The modular concept enables a customized configuration, while the robust design ensures long-term operational reliability. With low maintenance requirements and simple integration, Montech roller conveyors offer a convincing overall package for modern production and logistics processes.

Advantages of Montech roller conveyors

RB4020/5025

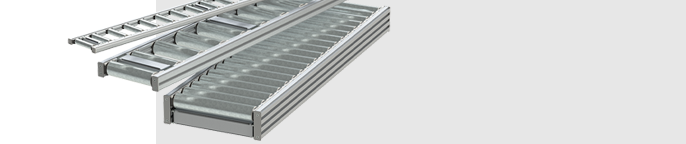

single-track

The gravity roller conveyors from Montech set new standards. Instead of predefined track widths, center distances or conveyer lengths, Montech offers freely selectable dimensions – accurate to a fraction of an inch and custom fit to the application.

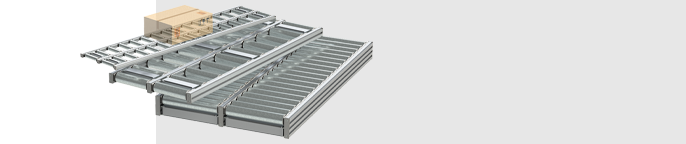

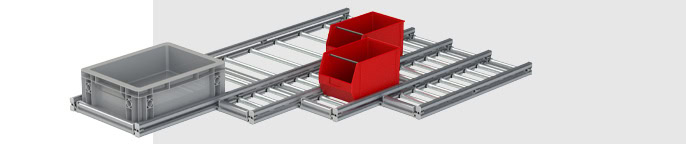

RB4020/5025

double-track

The double-track roller conveyor transports the product on two parallel tracks and therefore with twice the number of idlers – for maximum stability at high loads.

RB5025

tandem

Conveying width up to 2025 mm for large, bulky products. You determine the width of the support on both sides yourself – there is space in the middle for access from below.

RB4020/5025

multi-track

A personally customized roller conveyor system with several tracks. Different conveyer widths, roller spacings and track lengths – (almost) anything is possible.

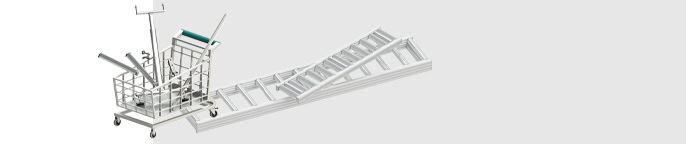

Accessories

and spare parts

In the store you will find accessories such as side guides and floor stands, but also idler rollers as spare parts.

|

Coming soon…Starting early 2026:Your roller conveyor configurator from Montech! |

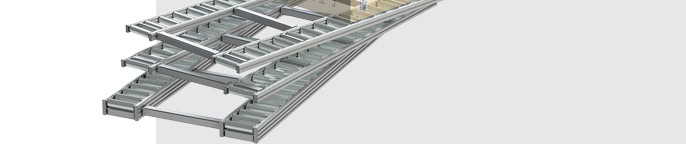

Precise construction for maximum stability

Our roller conveyors impress with their high-quality and thoroughly thought-through design. Two spars made of aluminum profile form the basis of the frame and are precisely connected to one another via connecting supports – also made of aluminum. This design guarantees maximum stability combined with low weight.

The number and design of the connecting supports are individually adapted to the respective conveyor load and width – resulting in a perfectly coordinated, durable frame structure. These frames are fitted with precision bearing steel idler rollers which ensure particularly smooth, uniform and low-maintenance running.

The result: a roller conveyor that impresses with its stability, precision and efficiency – ideal for reliable material flow in production, warehousing and logistics.