The challenge

To optimize functionality by integrating individual processing stations and material engineering paths into a limited production and processing area with greater flexibility. This required ensuring that there would be 2 machining processes with different requirements for conveyor speeds, as well as manual workstations with precise and reliable indexing devices.

The solution

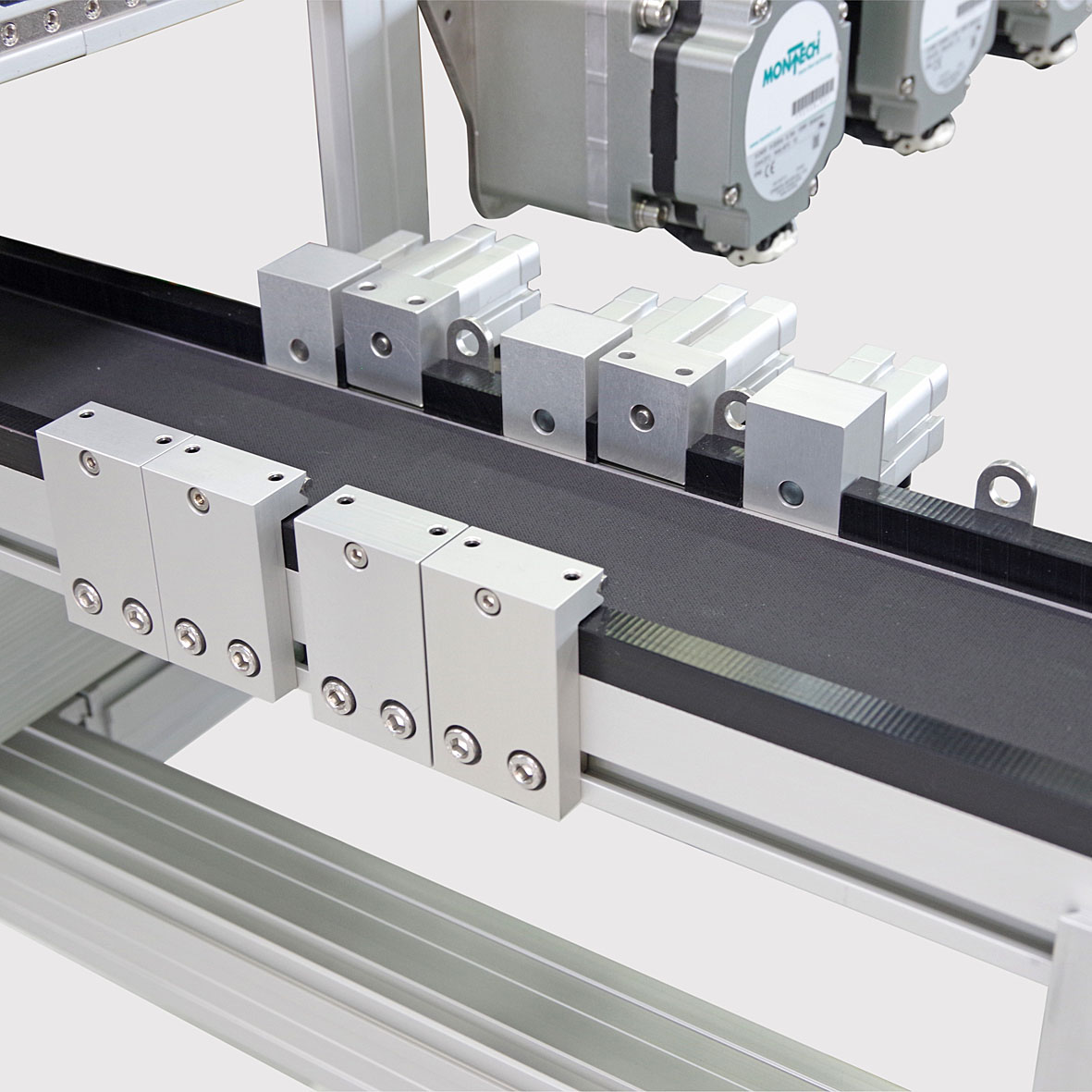

A square-shaped,

single-belt conveyor system supported on a stable

aluminum framing system substructure ensures continuous, safe buffering and testing of the goods conveyed on the workpiece carriers. In the square-shaped circulation path of the conveyor system, indexing stations for fully automated component testing are installed, as well as discharge using the independent conveyor with 4 individually controlled belt paths. This application-oriented, space-saving solution is able to buffer, test and classify the goods conveyed efficiently and safely, and then prepares them for the next work process.

Benefits for the customer

- Efficient, autonomous continuous processing

- Independent process expansion

- Easy, direct access to production cells

- Optimal use of production area

- Very flexible and adaptable

- Attractive and functional design

Discover additional

versatile solutions here.