The challenge

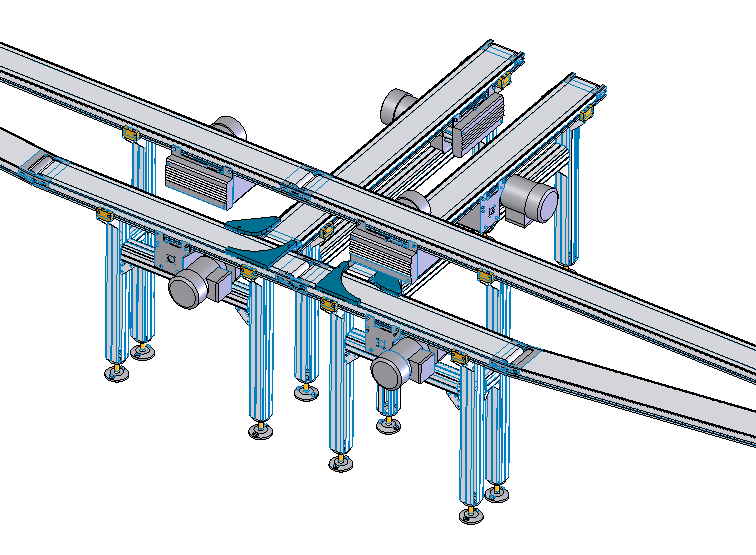

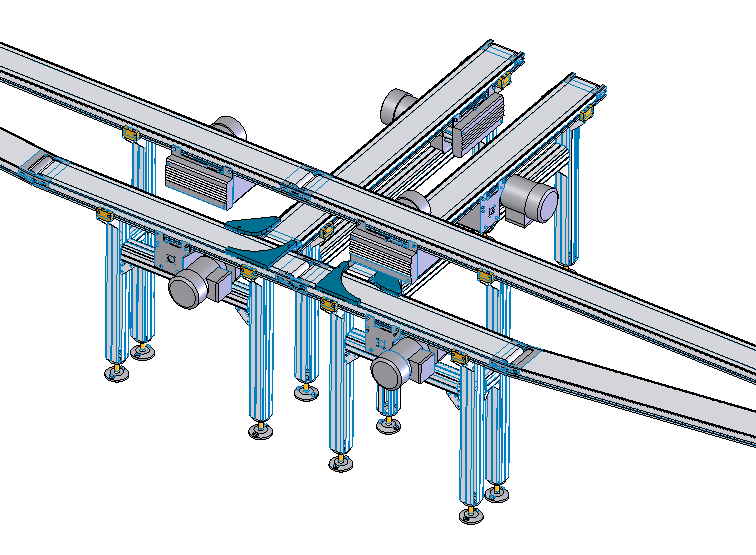

An integrator producing automation solutions and manufacturing systems for the pharmaceutical, consumer goods, automotive, and general mechanical engineering industries faced the following difficulties for an end customer in the packaging industry: In its production, two belt conveyors intersect due to the locations of the machines and there is therefore a risk of collision. The workpiece carriers come from the production machine to an inspection and removal station and must then be returned to the production machine. A lift or additional modules to avoid the crossing of the conveyor belts were not a solution because they would be too expensive.

The solution

We found the solution in a customer-specific longitudinal transfer system created with

TB belt conveyors. We have equipped these with belt bends. This gives the customer a second level, via which the workpiece carriers can be transported back to the beginning via the main line without the need for additional lift units or other expensive additional modules.

The customer benefits

- Custom-tailored solution

- Optimized work process

- A low-cost, low-maintenance solution

- Stabil, langlebig und platzsparend

- Continuous flow of goods with high cycle time across two levels

- Safe and uninterrupted transport

- Attractive, functional design

Discover additional

versatile solutions here.