The LT40 Transfer System Enabling Success for Brembo

References

"Small footprint, various processing phases and an attractive design – the demands for our demo line for the Polytechnic University in Milan were high, and the requirements were difficult to meet. In Montech we found a partner who offered us a solution customized to our needs in the form of the LT40 plus service in a class of its own; the transfer system was pre-assembled, tested and delivered very rapidly. The results are impressive along the entire line."

- Project manager: Jacopo Mora of Metalwork Service

- Project manager: Jacopo Mora of Metalwork Service

The challenge

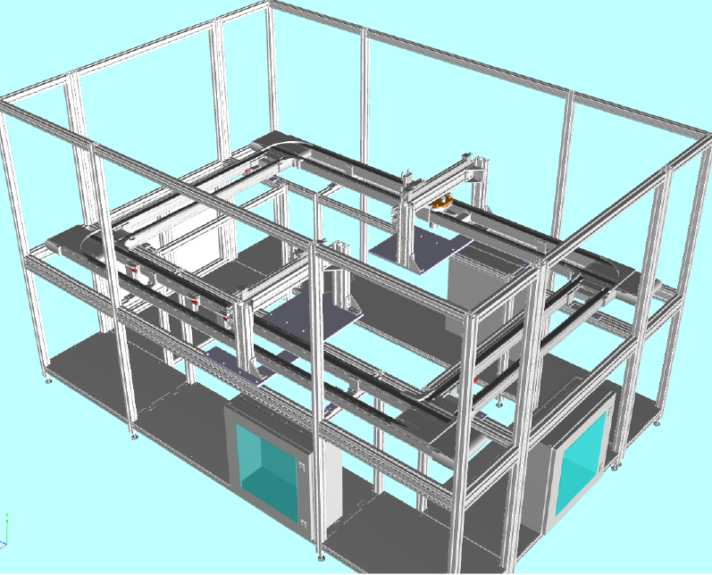

As a leading global manufacturer of brake systems and components for cars, motorcycles, and industrial vehicles, Brembo sought to create a demo line for the Polytechnic University in Milan. The line's purpose was to demonstrate various processing phases to future engineers. However, meeting the specifications proved intricate – the line needed to encompass four processing steps, incorporate centering procedures, and offer a flexible layout within a confined space. Additionally, the display required an attractive design.The Solution

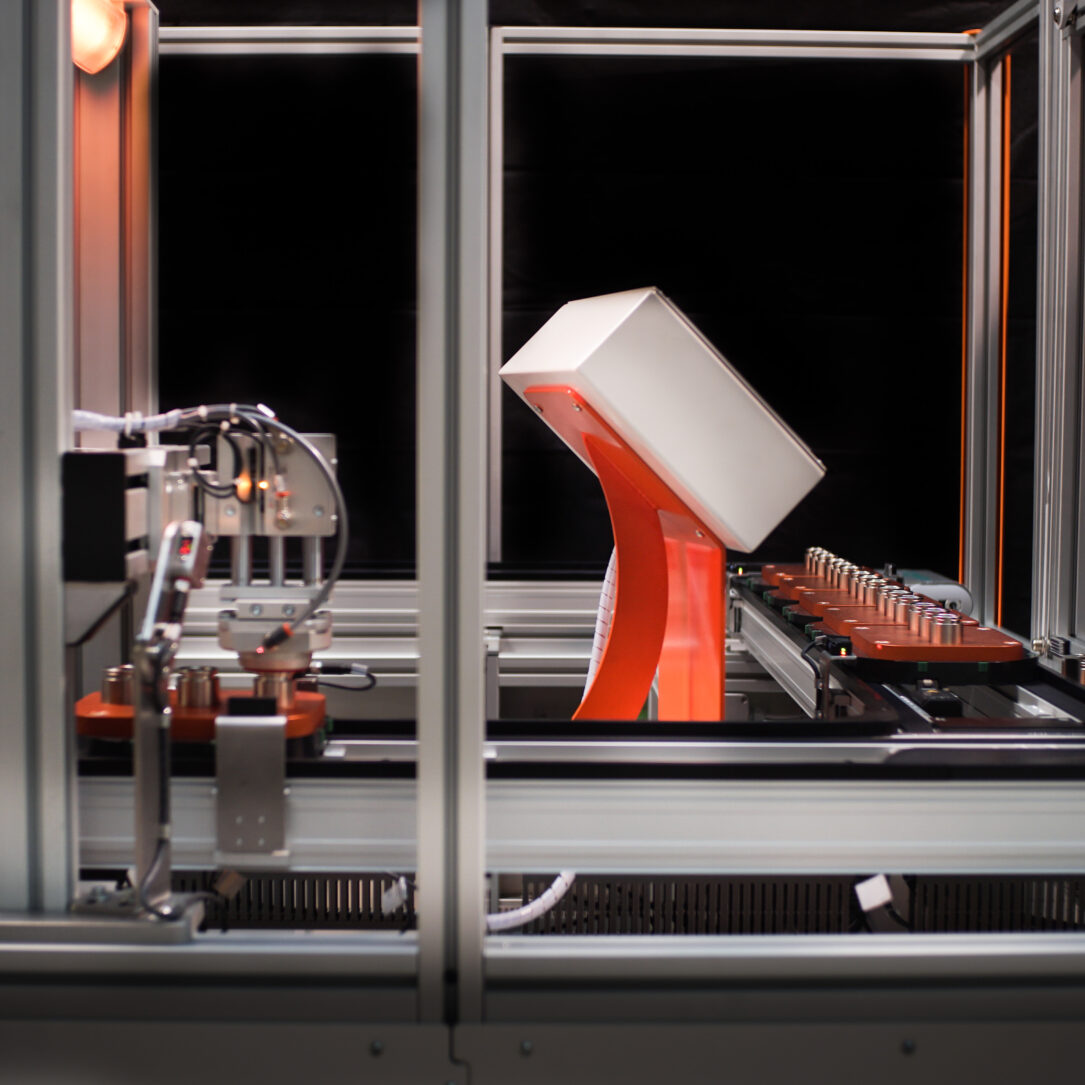

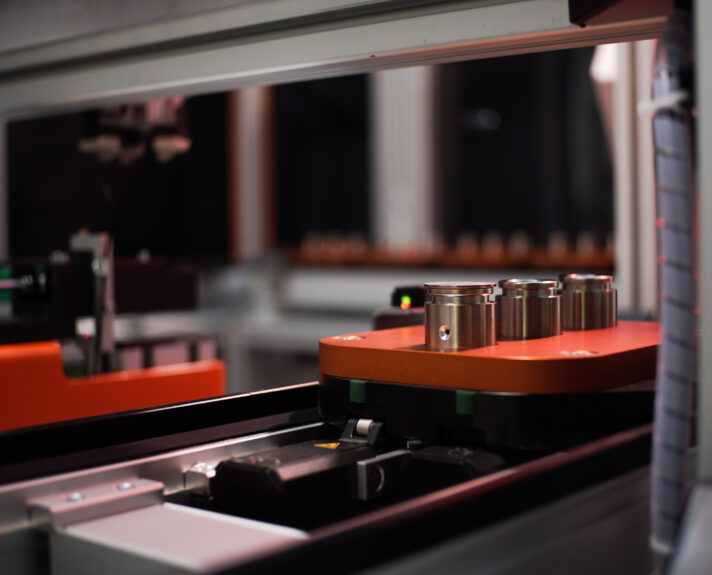

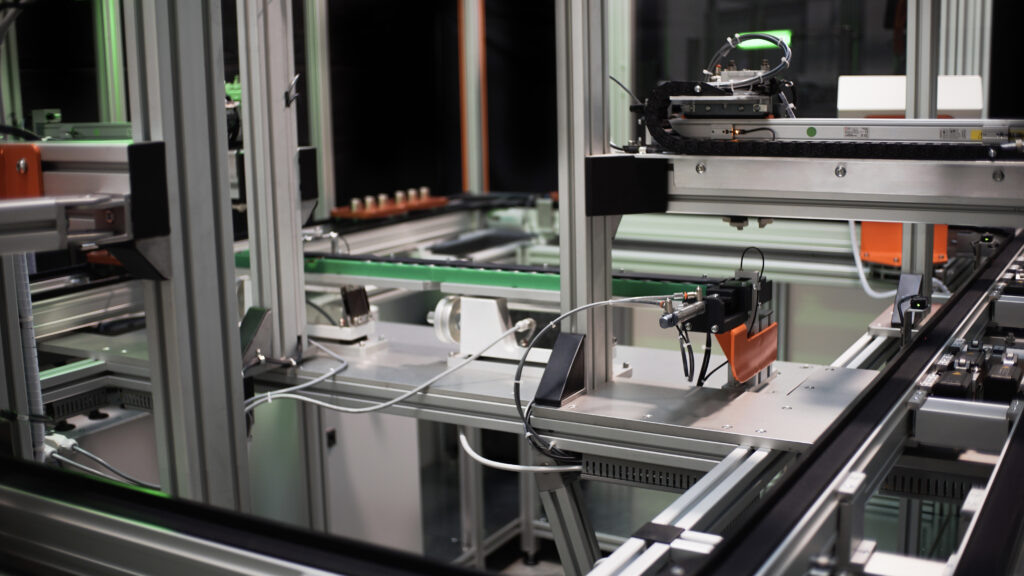

Montech’s LT40 transfer system proved to be the perfect match for Brembo's requirements. Operationally, the system effectively transported small items through multiple processing stages. Structurally, its compact design, driven by an integrated motor, allowed seamless utilization within limited spaces. The LT40's streamlined appearance further added to the system's appeal. For Brembo's demo line, the standard pallets of the LT40 were re-engineered with three stoppers at each of the four processing stations. This innovative design enabled pallets to halt and shift at each step, allowing for simultaneous processing of three different parts on a single pallet. This flexibility enhanced the efficiency of the processing steps at each station.The benefits for Brembo

- Optimal space utilization: The integrated motor enables a compact design.

- Tailored solution: Pallets and centering devices were re-engineered to handle complex operations at the workpiece processing stations.

- Versatile parameter management: Integrated brushless 24V motors offer speed and direction adjustments via digital and/or analog signals.

- Aesthetically pleasing design: Sleek and refined lines create a visually striking impact.

- Service excellence: The line was pre-assembled, tested, and promptly delivered to meet customer requirements.