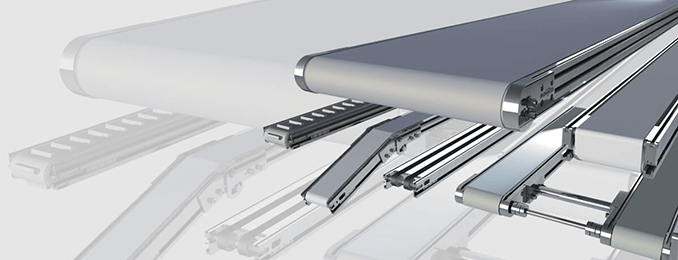

Belt Conveyors

Modular, Flexible, and Reliable

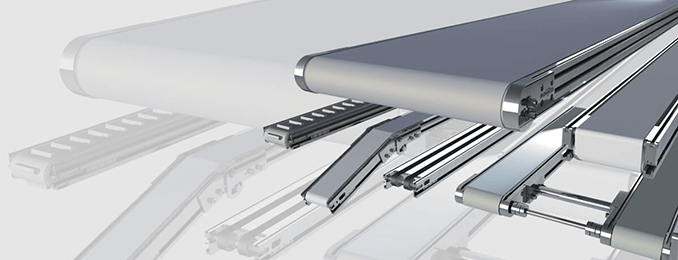

Montech’s belt conveyors stand out for their versatility and, thanks to their modular design, can be perfectly adapted to the requirements of industrial applications. They offer an efficient and flexible way to automate material flows – both in production and for in-house transport. In addition, Montech’s aluminum framing allow the construction of frames, machine guarding, and custom structures that can be seamlessly combined with our conveyor solutions.

This results in comprehensive and scalable automation systems – from transfer systems and roller conveyors to customized conveying solutions. Industries such as automotive, electronics, healthcare, packaging, and food rely successfully on Montech’s solutions.

Belt conveyor optimizes production

Using a belt conveyor instead of a manual material transport process is worth its weight in gold! Belt conveyors are found in all industries and are especially popular in the packaging, processing, and material handling industries. Conveyors move products and materials quickly and easily – even heavy objects. Increase the reliability and efficiency of the material flow in your production facility by automating with individual conveyors and conveying systems.

Your belt conveyor, your benefits

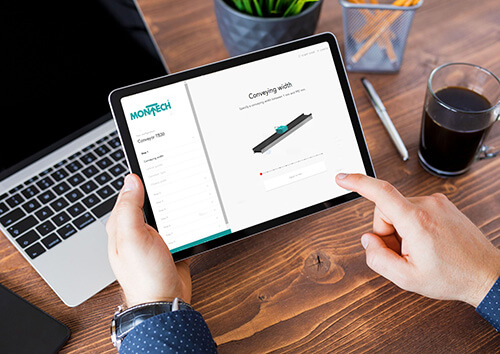

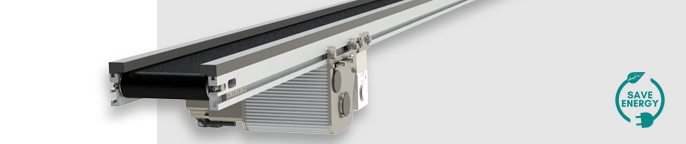

TB30 Single-Belt

The TB30 conveyor in single-belt configuration is perfectly suited for basic conveying requirements and can serve as the basis for customized conveying solutions. The modular design of the conveyor allows it to be easily modified for changing requirements.

TB30 Dual-Belt

The TB30 conveyor in dual-belt configuration is ideal when only a small contact area is desired and/or access to the product from below is necessary. The modular conveyor design allows for quick and easy assembly and reconfiguration, and can serve as the basis for customized conveying solutions.

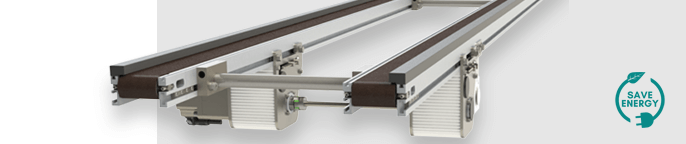

TB30 Tandem

The TB30 conveyor in tandem configuration is suitable for large, dimensionally stable products. The width and position of the support surface can be adjusted to optimally create the contact area to suit the product. Two conveyor chassis are cost-effectively connected with one coupling and drive, and is powered using only one motor.

TB40 Conveyor

With its modular construction, the TB40 conveyor can be easily configured to meet your production needs. Equipped with a 24 V brushless DC-motor integrated into the drive roller, the TB40 offers a compact design, with capability of loads up to 440 lb. Multiple belt types and accessories are available.

GTB Conveyor

GTB conveyors feature standard chassis widths up to 2.62″. Driven by a powerful 230/400 V or 460 V (UL) spur gear motor, GTB conveyors can move up to 275.57 lbs in conveying mode.

Cleanroom Conveyors

The cleanroom belt conveyors, tested by the Fraunhofer Institute, are certified for ISO 4 to ISO 6 under ISO standard 14644.

SOLTB Belt Conveyors

The SOLTB conveyors are built for handling light, delicate, and flat products.

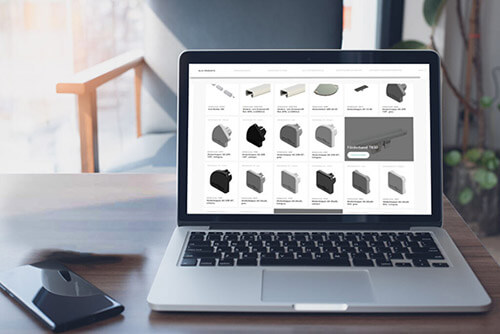

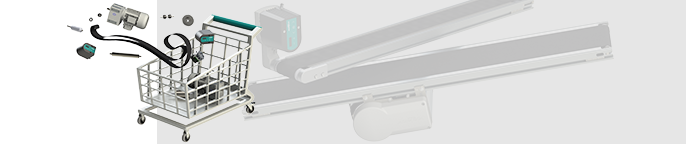

Accessories, Spare Parts

Montech offers various accessories to complement your conveyor, including lateral guides, floor and table stands. Our accessories are designed to integrate with other Montech modular components, making it easy to configure your conveyor.

Spare parts TB/KTB/BTB

New generations are replacing the TB, KTB and BTB conveyors. However, the supply of wear and spare parts is still guaranteed so that the existing conveyors can continue to provide reliable service for a long time to come.

Conveyors

Flexible, modular, versatile

For all our products, we rely on modularity, which makes our conveyors, cleanroom conveyors, transfer systems, aluminium framings systems, roller conveyors, and machine guarding flexible and versatile. This allows us to fulfill customer-specific requirements. The design is as simple as it is versatile. Various configuration options and a wide range of accessories allow for targeted adaptation to individual requirements and open up a wide and diverse range of applications – for tailor-made solutions at an attractive price with a short delivery time.

Conveyor systems

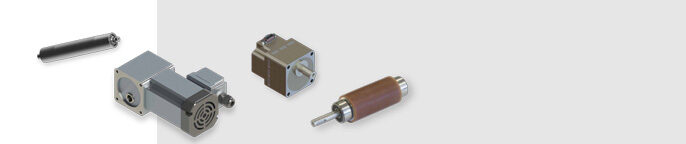

Innovative drive technology

The conveyor systems’ drive technology is also crucial for optimized conveying processes. Our conveyors are equipped with rubberized drive rollers that minimize power loss due to slippage. Your conveyor is driven by a three-phase or asynchronous geared motor, designed as a center or front/rear drive integrated into the drive roller, and featuring high power density and surprising additional functions. This innovative, energy-efficient drive technology with a minimal interference contour allows to be integrated even into confined spaces. Roller conveyors made of precise aluminum profiles can supplement and facilitate handling in the conveying process in order to save energy.

Suitable solutions

for conveyor technology

How efficient and economical your production or transport line will be also depending heavily on the conveyor technology you have selected. Whether you want to optimize your production or set up a new production area, Montech has the right solution for your needs. Our belt conveyors, cleanroom conveyors, transfer systems, and roller conveyors can be configured precisely to suit your requirements. Thanks to the modular design of our systems, you can design the material flow exactly according to your requirements and your space.