TB30 Dual-Belt Conveyor

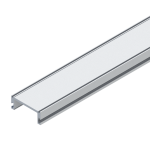

In addition to conventional product transport, the TB30 double-belt conveyor is particularly well suited for operations from underneath the product – like inspection, or assembly from below, as well as for edge transport of sensitive products.

A powerful drive unit, robust belts, and a modular design featuring standardized components make the TB30 dual-belt conveyor a versatile choice. The conveyor length and the distance between belts are manufactured to customer specifications. Power transmission to the belt is highly efficient, and without slip. A sliding plate insert is highly recommended for the chassis of the TB30 dual-belt, and mandatory when accumulation of product will occur.

A variety of standard chassis widths and drive configurations, as well as a wide range of accessories such as side guides and floor stands are readily available.

The TB30 conveyor is available in standard widths ranging from 4.13 to 9.84", and a maximum length of 32.8 ft. It is available as a single-belt or double-belt configuration. A tandem chassis version, driven by a single motor, is also available for the transport of larger pallets and other dimensionally stable products.

| Chassis widths | 4.13", 5.51", 7.28", 9.84" |

| Drive mode | end drive (front and rear drive), center drive |

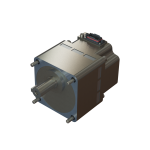

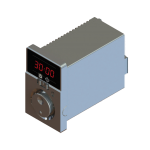

| Motor | Brushless DC motor preferably for variable speeds |

| . | three-phase asynchronous motor for fixed speeds |

| Power supply DC motor | 1x200 - 240V/50Hz or 1x100 - 120V/60Hz |

| Power supply AC motor | 3x380 - 420V/50Hz or 3x440 - 480V/60Hz |

| Speed: | . |

| DC motor with controller (infinitely variable) | up to 262.5 fpm |

| AC motor (fixed speed) | up to 98.4 fpm |

| Load in conveying mode | up to 174 lbs |

| Protection class DC motor | IP65 (controller IP20) |

| Protection class AC motor | IP44 |

| Warranty | 3 years |

| Delivery time | 2 - 3 working weeks with assembly |